How to Read a Forklift Data Plate

by David Tullis, on Feb 10, 2020 9:45:00 AM

It’s not enough for operators to know how to drive a forklift. It is essential that they be able to identify key information about the forklift to help ensure safe operation. Those important data points are required to be included on the forklift’s data plate.

What is a forklift data plate?

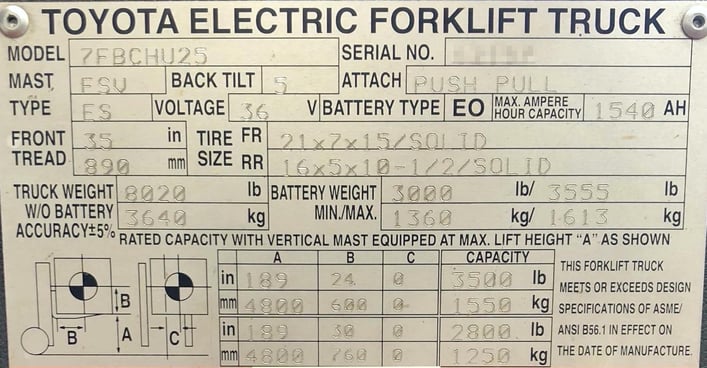

A forklift data plate is mounted on the forklift body and includes important information like the weight, fuel type, and overall forklift load capacity. A forklift data plate is sometimes called a capacity plate or a forklift nameplate. These metal plates are riveted to the forklift and feature easy to read writing that should remain readable for years.

What information is included on a forklift data plate?

A forklift data plate is designed so operators can quickly and easily learn essential information about the forklift. While specifics vary across manufacturers, most include:

- Forklift model number - this contains useful information, such as your forklift capacity.

- Serial number - this is key for technician communications and repair tracking.

- Mast type - this indicates whether it is a 2-stage, 3-stage, or 4-stage mast.

- Fuel type - indicates whether the forklift runs on electricity, liquid propane, diesel, gasolie, or compressed natural gas.

- Back tilt - indicates how many degrees the mast can tilt toward the forklift to help secure loads.

- Attachments - this shows what attachments (if any) have been added.

- Front Tread - the measurement of the overall width of the forklift.

- Tire size - indicates both the size and type of the tire the forklift uses.

- Truck weight - how much the forklift weighs without a load.

- Forklift Diagram - this shows several important measurements for calculating load weights and forklift maneuverability, such as:

- Horizontal load center

- Vertical load center

- Maximum fork height

- Maximum offset distance for forks from the centerline

How is a forklift’s load capacity determined?

A forklift’s load capacity is based upon its overall capacity rating as well as the load’s center. While your forklift may be able to lift up to 5,000 pounds, that max can be reduced based on the shape of the load you are moving. Longer load centers cannot weigh as much as shorter items due to the physics involved in forklift operation. Your forklift’s maximum capacity will be reduced by longer load centers, added forklift attachments, lift height, and other variables.

How are forklift data plates regulated?

OSHA and ANSI both require that each forklift attachment has an individual data plate. Aftermarket modifications and attachments must also be approved by the manufacturer prior to installation when they affect a forklift’s capacity, stability, or operation.

Per ANSI B56.1 Section 7.6.3, forklift capacities can be determined in two methods. Manufacturers can calculate the maximum capacity based on several factors including load centers, lift heights, attachments, and more. The second method involves chaining forklifts to a tilt table for more extensive testing.

Trying to lift a load that exceeds your forklift’s rated capacity can cause severe harm to operators and equipment. Training your operators on the importance of reading and understanding a forklift data plate is essential for keeping your employees and business safe.

Further Reading:

Check out our current Specials

4 Questions to Ask to Get the Full Value of Full Maintenance

5 New Year’s Resolutions to Improve Warehouse Safety