Bad Forklift Charger Repair Will Kill Your Fleet

by Theodore Taylor, on Dec 12, 2025 9:30:00 AM

The clock is ticking, and you’re staring at a tangle of wires, knowing the wrong move could spell catastrophe.

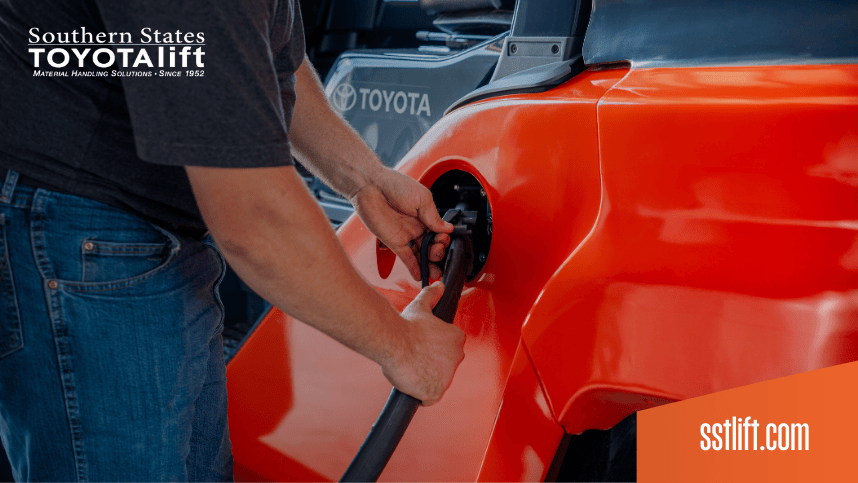

No, this isn't stock footage from the latest action movie. It's a reality that electric forklift fleet managers face whenever they use an inexperienced technician to work on their charging stations. A single mistake could take your whole fleet down for an entire weekend, costing you thousands in lost productivity and missed deadlines. When mistakes aren't an option, you need an experienced professional.

Read on to learn the most common mistakes in electric fleet operations and how to avoid them.

Small Electric Forklift Charger Mistakes Become Big Problems

Most often, it isn’t a big mistake that cripples your fleet; it’s the compounding of many smaller mistakes.

Imagine this scenario: You have an inexperienced but inexpensive technician come in to install a few new connectors on your electric forklifts and batteries. It’s a simple enough job, and when it’s complete, everything seems fine. Yet, the technician made a little mistake.

They accidentally installed one of the connectors backwards.

It's easy enough to do, and it goes unnoticed until the operator tries to charge the forklift. They connect the battery only to find that the forklift battery charger isn't charging. The technician scratches their head and thinks, "That's weird. The battery worked fine all shift. Must be a bad charger." So, they move down the line, trying each charger in turn.

It's easy enough to do, and it goes unnoticed until the operator tries to charge the forklift. They connect the battery only to find that the forklift battery charger isn't charging. The technician scratches their head and thinks, "That's weird. The battery worked fine all shift. Must be a bad charger." So, they move down the line, trying each charger in turn.

Only none of the charging stations work.

Other operators bring their forklifts around and discover the same issue. No one can figure out what happened. The chargers were working earlier. Now, the whole fleet is down, and you’re making an emergency call to your electrician.

Unfamiliar with forklift charger repair, the electricians don’t know what to look for.

Almost by accident, they discover every single charger has the same fuse blown. It's the DC output fuse that protects the charger from reverse-polarity currents, such as those caused by a backward connector. None of the generalist electricians know what could have caused this, and worse, it's not a standard fuse they have in stock. They'll have to order it, and they can't guarantee that it will fix the problem. As the cost of repair and lost downtime pile up with no assurance of a permanent solution, you're looking at an expensive band-aid at best.

Unfortunately, this scenario is all too common, but a single, experienced technician could have prevented it all.

Common Electric Forklift Fleet Mistakes

Every forklift charging station has specific requirements, and they aren’t always intuitive.

Yet, failing to keep these requirements front of mind can lead to system-wide failures. These mistakes are staggeringly easy to make for anyone who isn’t an electric forklift expert.

- Mismatched operating specifications. Every battery has voltage and capacity ratings, and the charger must have ratings to match. This becomes an issue when fleet managers upgrade batteries and fail to upgrade their chargers as well.

- Mixed fleet batteries. Facilities moving from lead acid to maintenance-free sealed batteries, like lithium-ion, run into this challenge often. Standard chargers for lead acid batteries are incompatible with sealed batteries, regardless of the connectors used. Charging an incompatible battery even once can cause permanent damage.

- Mistaken connectors. Even when you match the correct charger to the right battery, mistakes can still happen. Many connectors appear similar, making it easy for operators to hook up the wrong connector by accident. Color-coding or using different style connectors for each battery/charger combo is the best way to protect your mixed fleet.

These examples focus on common mistakes made by operators and fleet managers. However, there are many more that an inexperienced technician can make during forklift charger repair.

The only way to fully protect yourself from these expensive mistakes is to work with professionals who have extensive experience in electric forklift charger installation, maintenance, and repair.

The Right Forklift Charger Repair Saves Your Fleet

Just like an action hero trying to disarm a bomb, you need access to experienced professionals to ensure that adjusting the wrong wire doesn’t put your fleet out of commission.

We have decades of experience installing charging stations, upgrading forklift batteries, forklift battery charger troubleshooting, and converting from IC to electric fleets. There’s a reason industry leaders like Astin Farms and Ceres Marine trust us. We know forklift charge repair backwards and forwards, ensuring your fleet is always ready to save the day.

To learn more about how an expert technician saves you money in the long run or to request a quote, contact us online or visit one of our locations:

Florida

Jacksonville

Lakeland

Ocala

Orlando

Tampa

Winter Haven

Georgia

Albany

Macon

Columbus

Valdosta

Further Reading

We Can Fix That: A Short List of Everything We Service and Repair

Are Lithium-Ion Forklift Batteries Right For Your Business?

4 Things To Consider When Converting to Electric Forklifts